SMC production is relatively very difficult and we can handhold from scratch to part production and inspection, installation of the machines can also be done

We can guide on complete factory layout with machine and raw materials placement for effective and economical production solutions.

SMC raw material composition for finer part end results is a very complex process, we have 30 years of experience and expertise to guide on most complex formulations with details on specific additives to achieve Class A finish and also for best fire properties amongst others

We have experts who can source all raw materials and machinery for complete SMC production. These include big capacity SMC Hydraulic presses, High precision Moulds, Robots and other associated machines. SMC raw materials to suit the specified product can be sourced for companies who do not have SMC lines. We can sources from Europe, South Korea, Taiwan, India and China

SMC Tech has the skills and capabilities to machine all components of the Moulds at various locations and assemble them to deliver the complete Moulds as per the specified drawings

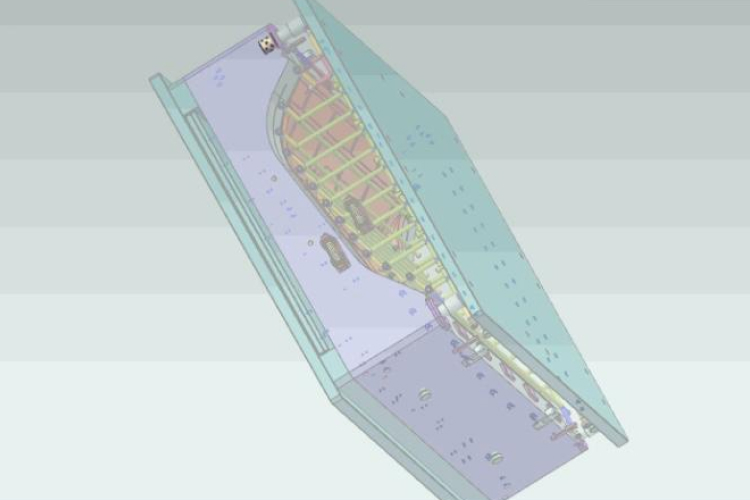

Once the SMC part is designed we have the expertise and software to design SMC moulds with all details to suit the part production. The Mould design will be in IGES format and ready for machining software

We have competent engineers to design parts post concept drawing for compatibility to SMC production providing a host of benefits like weight reduction and stress free part design.

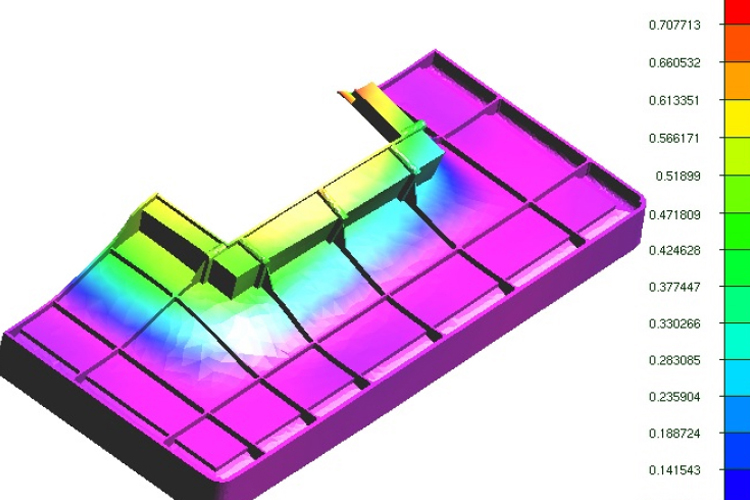

To optimise the functionality of the SMC part and the Mould we have the expertise to do Finite Element Analysis to validate the design

We have partners across the globe to do third party inspection on Machines and Raw materials to see that the best quality as promised is delivered to the customer

We have the technical expertise to train your staff to understand the SMC production process and successful production of SMC parts